- back

- Description

- Technical Specifications

- Hole Specifications

- Matching Products

- Processing

- Packaging

- Downloads

- Stock Check

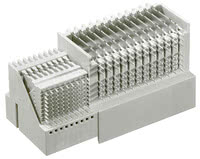

MTCA Power Module Output Part No. 501-50096-183

Illustration similar

Perpendicular

Press-fit

Power

Rugged

- contacts: 72 signal, 24 power

- Press-fit

- according to PICMG specifications

Technical Specifications

Basics

| Specification | PICMG® MTCA.0 R1.0 |

|---|---|

| No. of Contacts | 96 (24 Power, 72 Signal) |

| Termination Technology | Press-fit |

| Termination Length | 3.5 mm |

| Operating Temperature Range | -55°C to +105°C |

Material

| Insulator Material | PBT glass filled, UL 94 V-0 |

|---|---|

| Contact Material | Copper alloy |

Mechanical

| Mating Force | max. 50 N |

|---|---|

| Separating Force | max. 50 N |

| Durability | 200 mating cycles |

Electrical

| Operational Current | Power contacts: max. 12 A, Signal contacts: max. 1 A |

|---|---|

| Insulation Resistance | ≥ 108 Ω |

| Test Voltage | 80 V r.m.s. |

Approval / Compliance

| UL file | E130314 |

|---|---|

| Environment | RoHS compliant |

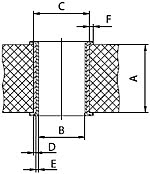

Hole Specifications

| Material | imm. Sn printed circuit boards |

|---|---|

| Nominal Hole | Ø 0.6 mm |

| A PCB Thickness | min 1.44 mm |

| B Plated Hole | Ø 0.60 ±0.05 mm |

| C Drill Hole | 0.70 ±0.02 mm |

| D Cu Plating | min. 25 µm |

| E Surface | max. 1.5 µm; imm. Sn plating |

| F Annular Ring | min. 0.1 mm |

| Material | Ni, Au printed circuit boards |

|---|---|

| Nominal Hole | Ø 0.6 mm |

| A PCB Thickness | min 1.44 mm |

| B Plated Hole | Ø 0.60 ±0.05 mm |

| C Drill Hole | 0.70 ±0.02 mm |

| D Cu Plating | min. 25 µm |

| E Surface | Ni, Au plating, 0.05 - 0.2 µm Au over 2.5 - 5 µm Ni |

| F Annular Ring | min. 0.1 mm |

Plated through-hole according to IEC 60352-5

Matching Products

Processing

Packaging

Tray

15 pcs / Tray

4 Tray / Box